Limestone Calcined Clay Cement (LC3) Workshop

Cora Structural was a guest at a recent workshop on “Unlocking Cement Decarbonization with LC3” featuring Dr. Karen Scrivener and other top global researchers, industry experts, practitioners, and clients. The event was co-hosted by RMI and Climateworks, and included presentations and discussions on the role of Limestone Calcined Clay Cement (LC3) and calcined clays in decarbonizing the cement industry. The workshop took place at City Club of San Francisco on the week prior to the Spring ACI Convention. Dr. Karen Scrivener of the LC3 project and Scott Shell of Climateworks wrote up a fantastic brief on LC3 and its potential for scaling up the decarbonization of the cement industry following the workshop. We think you’ll see tremendous value in the potential of LC3 in the overall movement of decarbonization. We highly recommend your read it:

The workshop was a great opportunity to connect with a range of cement industry stakeholders and provide a structural engineering perspective as both a practicing structural engineer as well as a steward of the national SE 2050 Commitment Program and its mission of achieving net-zero embodied carbon structures by 2050. One takeaway we had was on the importance of knowledge-sharing and trying to understand the perspectives of all parties. If we have any chance to meet the global CO2 targets we cannot do it in silos and this workshop completely corroborated that notion. Until we attended this event, we did not fully grasp the potential that LC3 could have on reducing the embodied carbon of concrete particularly as the availability of high quality supplemental cementitious materials (SCM) like slag and fly ash for clinker replacement level off. Being part of the conversations on the complexities of the cement and SCM supply chain, both domestically and internationally, helped us understand a bit better how things can be translated locally to current projects and when speaking with clients. As with any movement its imperative to understand the right questions to ask and we certainly heard a few we’ll be asking in our daily practice.

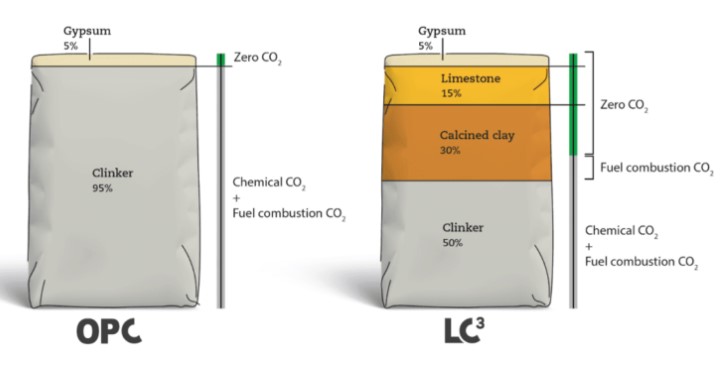

It was particularly wonderful to hear Dr. Karen Scrivener speak about LC3 – her expertise and drive to move the cement industry forward was inspiring. From her presentation, and others, we became educated on the scalability of LC3 by the simple fact that availability of adequate clays to create LC3 is significant globally and that calcining them can be done at a much lower rate of CO2 emissions. Its being produced in the United States, TODAY, and the potential for cement producers to produce and supply with modest upgrades to existing technology exists now.

The workshop reminded us of a great article that summarizes solutions to decarbonizing the cement industry from a global perspective. We feel this is one of the ‘go-to’ articles providing the full picture tied to the global decarbonization movement. See below.

So what to do with this information?

As structural engineers we must not only educate ourselves but educate our clients to put them in the best position to achieve their goals. The present day structural engineer must engage more on this topic, understand where opportunities exist on projects and find ways to implement all while satisfying present day project constraints. It can be done. The first step is to educate yourself and then ask your fellow colleagues some basic questions to get started:

- To the General Contractor / Construction Manager

- “What do you know about this low-carbon concrete movement?”

- To the Concrete sub-contractor (on your current project if possible)

- “Have you ever installed concrete with a portland cement replacement rate higher than 30%?”

- To the Concrete ready-mix supplier (on your current project if possible)

- “Have you been having any issues getting fly ash or slag?”

- “Do you have any test data on concrete’s with portland cement replacement rates higher than 40%?”

- To the Structural Engineer

- “Are you comfortable specifying concrete with portland cement replacement rates higher than 30%?”

Just by asking those basic questions you’ll open up a great opportunity to learn more than you ever thought you would!